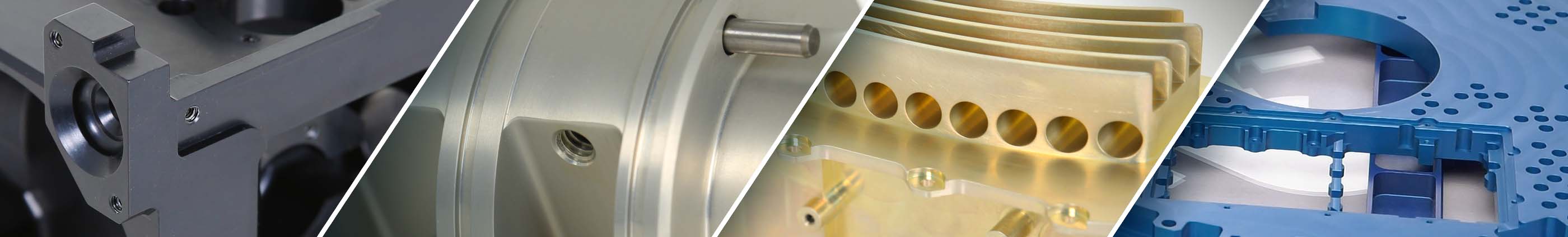

Evolving high-tech industries require precision-manufactured components and assemblies to achieve critical performance improvements. Our innovative manufacturing solutions meet customers’ most challenging requirements. Whether machining tight-tolerance parts or completing value-add assembly services, our comprehensive in-house capabilities give customers a cutting-edge advantage.

Components and assemblies for energy applications must withstand high pressures and extreme temperatures. With our knowledge of machining high-nickel-based alloys and alloys ranging from 304L VAR to H900 condition 13-8PH to API 6A718, we support subsea product requirements for the energy sector. We also manufacture parts from various Nitronic grades and Hiperco.

We support a wide range of OEMs in evolving high-tech industries as well as Tier 1 and Tier 2 suppliers. Industrial manufacturers in need of complex, tight-tolerance components and assemblies leverage our collective engineering and precision-machining expertise to optimize their success in critical applications.

For critical components requiring assembly in an ultra-clean environment, OEMs turn to us for our clean-room assembly services. Our tested and calibrated final assemblies adhere to your strictest cleanliness requirements. Highly trained technicians assemble your components in a clean room rated at 10,000 ppm with a Class 1,000 hood.

Align our expertise with your next program

CONTACT