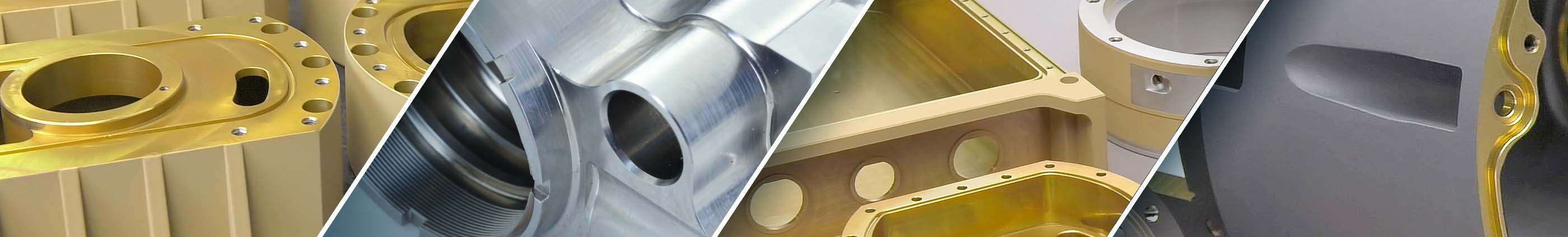

Defense OEMs need a trusted partner for the contract manufacturing of its tight-tolerance parts, components, and assemblies. ALIGN PRECISION is armed with a breadth and depth of machining and manufacturing capabilities to produce intricate, fracture-critical components in aluminum, hard metals, high-nickel-based alloys, and other exotic materials.

Equipped with the latest machines for multi-axis CNC milling, turning, and grinding plus sheet-metal hydroforming and fabrication, our support encompasses all areas of precision manufacturing. We produce complex components with advanced geometries as well as provide finishing and assembly services.

ALIGN PRECISION deploys our full arsenal to meet the industry requirements for our defense customers. We consistently deliver exacting quality using the latest technologies, techniques, and equipment. Our teams adhere to stringent processes and standards to ensure our quality and performance are always on target.

Our teams possess the knowledge and skills to provide high-quality precision-manufactured solutions—from micro to large envelope—for a wide range of demanding applications. We have produced fracture-critical components and complex subassemblies for remote weapons systems, missile systems, Navy fleet, and state-of-the-art fighter jets. We are capable of machining tight-tolerance components in titanium, steel, or stainless steel in a heat-treated condition or high-nickel alloy.

Align our expertise with your next program

CONTACT